2022.01.22

Although we have only had our new boat for a couple of months, we were able to get out and have a few nice lunches at anchor. While the stock Lewmar 'Bruce' style anchor works find for lunch stops like this, the general consensus is that it is not suitable for overnight mooring if the weather comes up. Although there are lots of different styles of anchors for all kinds of purposes, the most popular option in our area is the Rocna, and for our size boat, the recommended version is the Rocna 10 (10kg/22lbs).

But you know how it is - once you upgrade one thing, you have to upgrade something else. When the beefy Rocna arrived, I looked at the anemic little shackle for our current anchor and knew it would not do. I decided to upgrade to the Mantus anchor swivel, which along with being super stout, allows the anchor to swivel and prevents the line from getting twisted up.

With our new swivel and anchor, we hope to be able to anchor out in the San Juan Islands and other places in Puget Sound. But our boat only came with ~135 ft of rode (125' of rope and 10' of chain). Since the credit card was already out, I decided to replace the rode as well and ordered 300' (275' of rope and 25' of chain) from Seco South. The new rode is 8-plait which is supposed to lay flatter in the anchor locker and not get twisted up on itself. (Even in our few lunch anchoring so far, the existing 3-strand line that we had often got twisted up).

One side effect of the new Rocna anchor is that it is much bigger than the old anchor. Since Ranger Tugs have a fairly vertical bow, it means that the sharp point of the anchor could hit the hull. One solution is to use the Mantus AnchorGuard (aka AnchorMate) with the stock bow roller to keep the point safely away from the hull and several Tugnutters reported success with this. But the stock bow roller is pretty small and just didnt seem to be up to par with the other new components.

One solution is to replace the entire bow roller, but the bow rollers are bolted to the hull in a way that makes the bolts inaccessible after the boat is built. A few people drilled a 5" hole in their anchor locker to access the bolts and installed an inspection plate to cover the hole. While that makes sense, I couldnt bring myself to drill a giant hole in our boat.

But one ingenious boater realized that you could use the existing bow roller as a mounting point for a new bow roller - effectively removing the need to drill the hole. This turned out to be a popular solution, and nearly everyone used the Mantus BR1 bow roller for this modification. The reason is that the BR1 has a flange that allows it to be bolted through the existing bow roller.

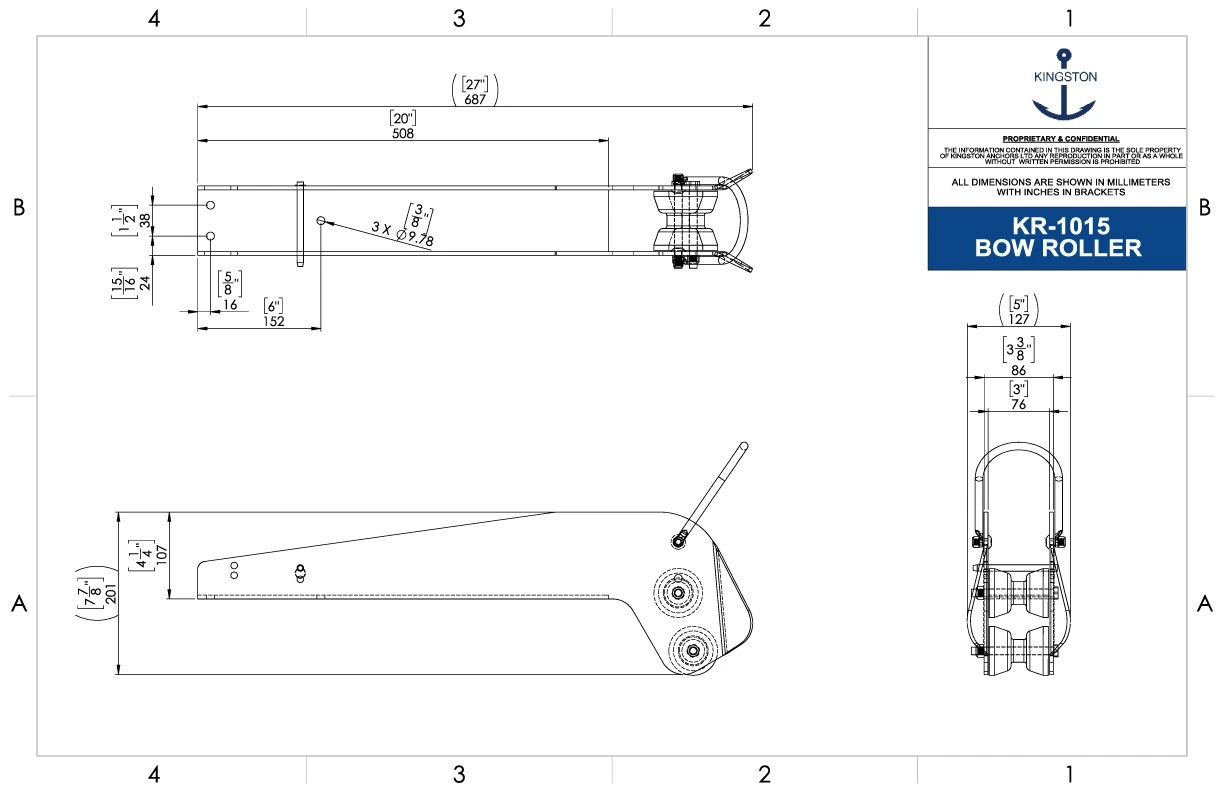

I was going to follow suit and do the same, but the BR1 solution still had some drawbacks. The anchor could still hit the hull, so you still need to use the AnchorGuard as well. Nothing wrong with that - both the BR1 and AnchorGuard are solid products, but I wanted an integrated solution. I did a ton of research and stumbled upon the Kingston KR-1015 - it is made in Canada and is specifically made for the Rocna anchors and doesnt require any extra pieces. Because of the design, I thought it might work for my custom application.

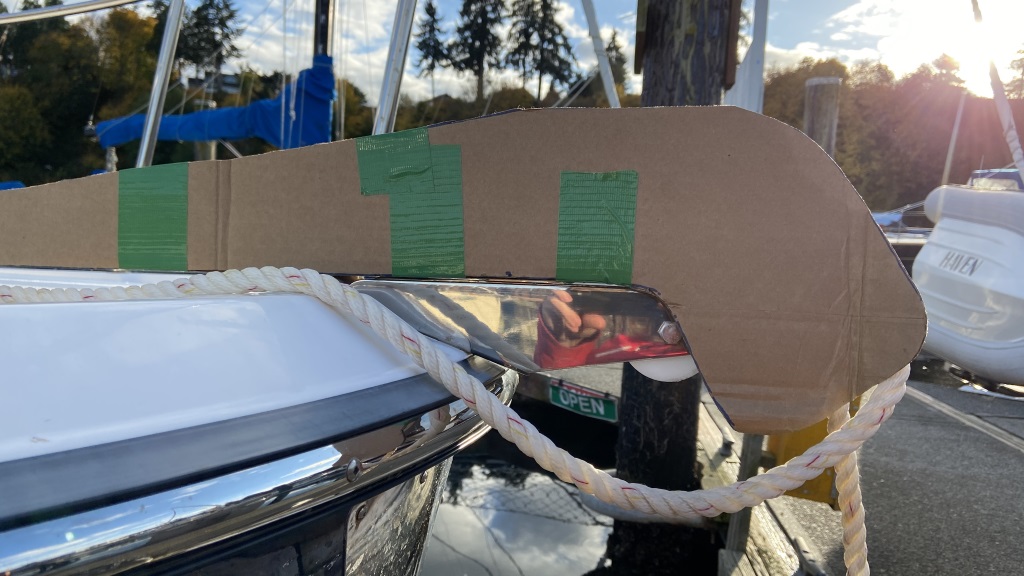

One great thing about the Kingston bow roller is that they provide detailed mechanical drawings that give all of the dimensions. Because of this, I decided to make a cardboard mockup of the bow roller to try out on our boat to see how it would work before committing.

This test fitting confirmed that the bow roller would work, so I decided to order it. When it arrived, I was very happy to see that it was exactly the same dimensions & shape as my mockup.

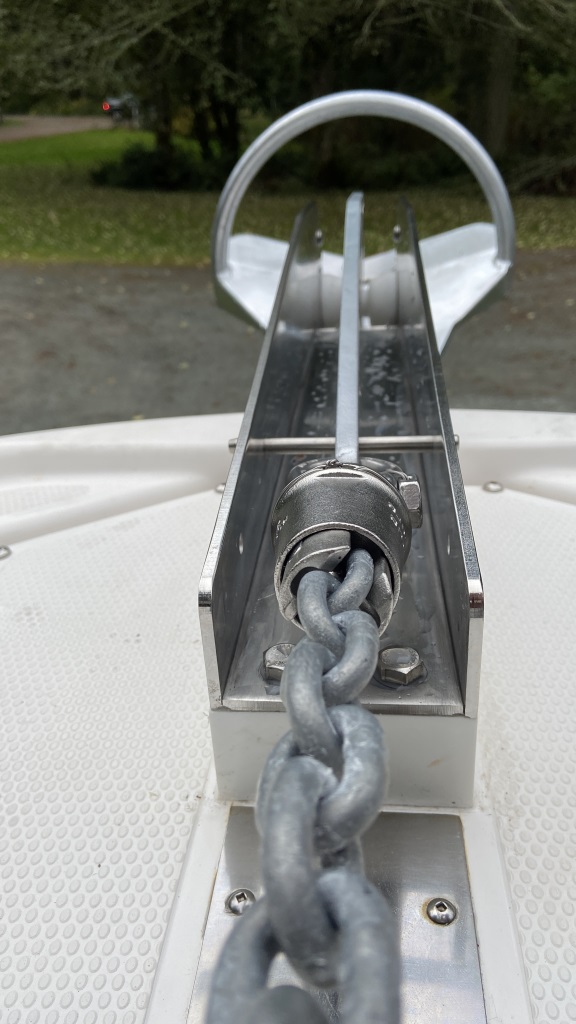

Because the Kingston bow roller was designed specifically for the Rocna, it was of course a perfect fit:

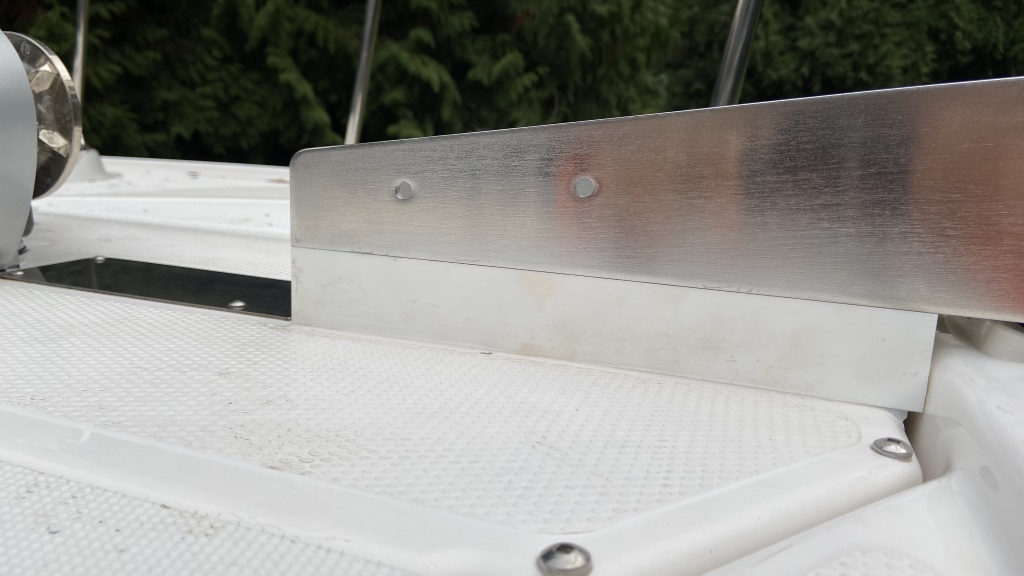

With all of parts now acquired, now was the fun part of installing it. Because of the design of the Ranger Tug deck and the shape of the existing bow roller, I needed a spacer block to raise up and level out the new roller. I bought a piece of King Starboard from TAP plastics - they have a bunch of thicknesses available and you can have them custom cut it to any size. I needed a 1.5" thick piece, 3 3/8" wide, and 12" long (I got it a little long so I could cut it to the exact length as needed). I also got a 3"x12" piece of stainless steel plate to use as a backing plate on the underside of the deck.

The key piece of the puzzle was to drill a hole through the new bow roller that would allow a bolt to pass through both the old and new bow roller. I measured five times to be sure of the location and then drilled the hole through the new bow roller. (Drilling through the 3/16" stainless steel was challenging).

I put everything temporarily in place on the boat and lined up the new roller with the old roller. I drilled through the old bow roller with the new one in place and put in a new 4" 3/8" stainless steel bolt through both.

With the stainless steel backing plate underneath, then the deck, then the starboard spacer, the new bow roller sat perfectly in position. I used some BoatLIFE Life Seal sealant between each piece and around all of the bolt holes to prevent water from getting into the deck core.

Now that the new bow roller was in place, I loaded up the new anchor rode and Rocna anchor. The Kingston roller even has a locking pin built in to secure the anchor when stowed.

The only bad part is that the boat is headed into winter storage so we will have to wait until spring to try it all out.

@briandunnington

@briandunningtonSome winter fatbiking and camping to kick off a new year of microadventures

We had a big windstorm blow a tree down but made the best of it

Upgrading our solar setup for energy independence

A few small upgrades for the boat and an end-of-summer trip to the San Juan islands

Replacing the shore power plug with a SmartPlug and adding a galvanic isolator